Advanced Robotics For Industry: Transforming The Future Of Manufacturing

Robotics and Environmental Impact

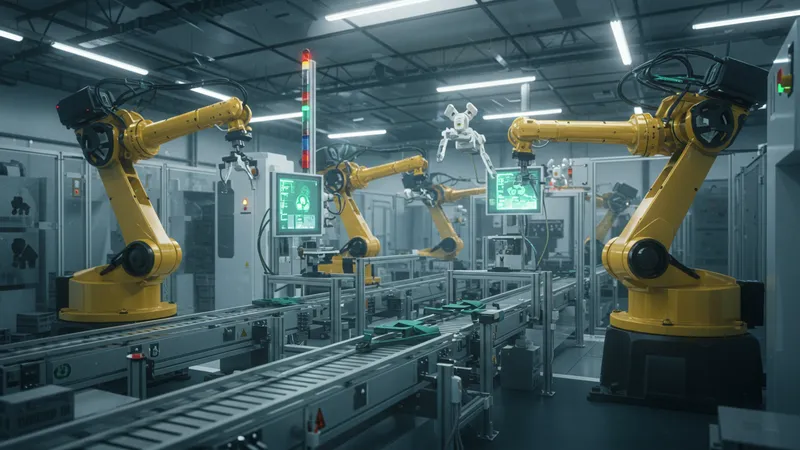

The environmental implications of robotics in manufacturing encompass both positive advancements and critical challenges. On one hand, automating production lines leads to sustainable practices through precision manufacturing, which dramatically reduces waste and energy consumption. This alignment with carbon footprint reduction goals illustrates an advantageous position robots hold in the fight against climate change.

Innovative companies exploit advanced robotic systems to implement circular economies, recycling and reusing materials with unprecedented efficiency. By minimizing waste, businesses not only meet eco-friendly agendas but potentially realize substantial cost savings. This dual benefit incentivizes wider adoption of robotic technology within sustainable business models.

Conversely, the production and disposal of robots introduce environmental challenges. The sourcing of rare minerals and energy-intensive manufacturing pose dilemmas that industries continue to navigate. Establishing comprehensive recycling programs and sustainable resource chains becomes vital to mitigate these effects.

The broad narrative is clear—although robotics offers a route to ecological preservation, responsibility remains paramount. Realigning environmental strategies ensures that the benefits of innovation do not come at the expense of our planet’s health. But the solutions to these pressing challenges might surprise you…