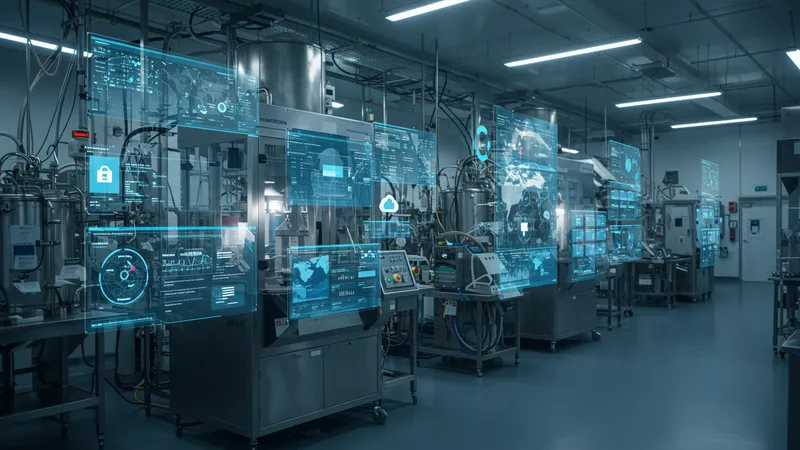

Digital Batch Record System For Modern Pharmaceutical Manufacturing

System Integration and Scalability in Pharmaceutical Digital Batch Records

Integration with existing enterprise systems and scalability are top priorities when selecting a digital batch record system for modern pharmaceutical manufacturing. Implementations must accommodate a wide array of hardware, software, and process complexities found in diversified manufacturing environments. Platforms like MasterControl and Rockwell FactoryTalk are developed to support both plug-and-play with existing infrastructures and extensibility for future requirements.

As manufacturers expand geographically or add new product lines, the ability to scale digital batch record solutions efficiently becomes paramount. Cloud-hosted options, as available in TrackWise, facilitate quick adaptation to changing plant requirements without large on-premises IT investments. These systems can be deployed across multiple locations, ensuring consistent batch recordkeeping globally, while centralizing updates and security protocols.

The integration between batch records and manufacturing equipment (e.g., distributed control systems or automated samplers) opens opportunities for direct data capture, which improves accuracy and speeds quality checks. This seamless connection supports initiatives like continuous manufacturing and real-time release testing, which are growing trends among advanced pharmaceutical producers.

Properly managed, systemic integration unlocks powerful cross-functional insights. Data trends identified through batch record analytics can inform process optimization, root cause analysis, and predictive maintenance initiatives. As digital batch record systems continue to evolve, their ability to accommodate both current and future manufacturing needs provides manufacturers with an adaptable, future-proof solution.