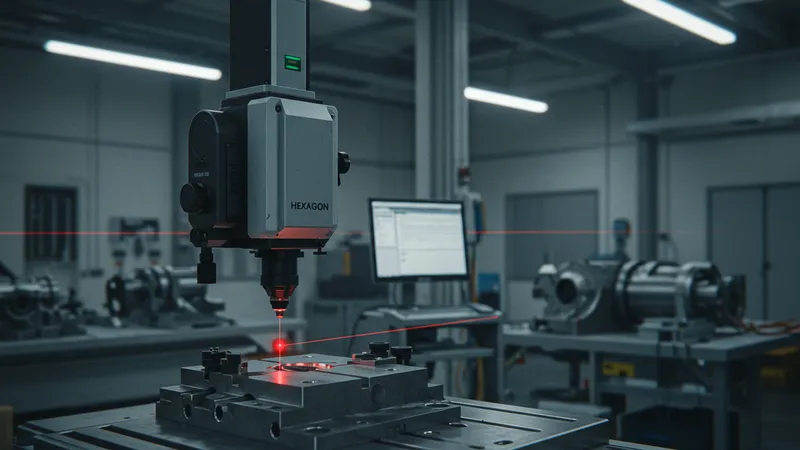

Hexagon Metrology Solutions For Businesses

Why Businesses are Opting for Hexagon Over Traditional Methods

Conventional metrology methods, long relied upon for quality assurance, are being sidestepped for the reliable precision offered by Hexagon solutions. Traditional approaches, often cumbersome and fraught with inconsistencies, pale in comparison to the scalpel-like precision Hexagon metrology brings.

Manufacturing units find themselves caught in a loop of perpetual adjustment and recalibration with traditional tools, losing valuable time and resources. This is where Hexagon metrology solutions disrupt the norm, offering incredibly low error margins and seamless operation that saves both time and money. But that’s not where the story ends…

The word on the street is that businesses embracing Hexagon’s offerings report up to a 45% increase in efficiency within the first year. This isn’t just about leaps in productivity but significant reductions in waste and overheads, transforming balance sheets overnight. But the intriguing benefits don’t stop there…

Picture an environment where equipment talks to systems, updates itself, and preemptively resolves issues. Hexagon metrology embodies this futuristic vision, and what’s coming next will flip your expectations on their head…