PCB Design Solutions For Medical Devices

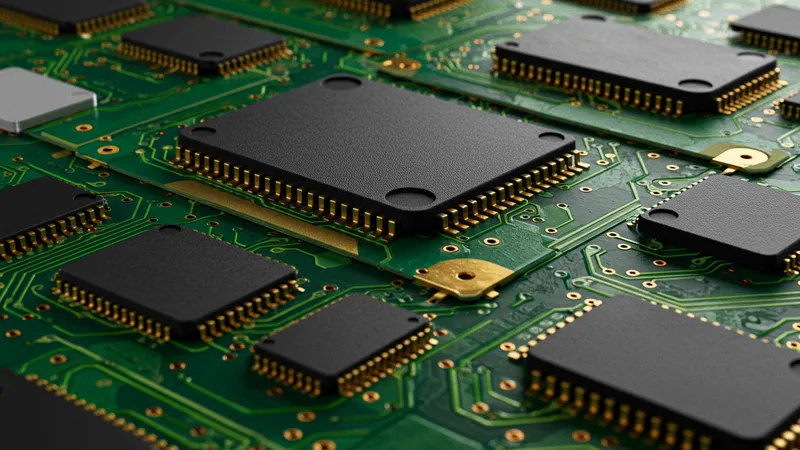

PCB Materials: The Unexpected Heroes

One might not suspect it, but materials used in PCB production play a pivotal role in the performance and reliability of medical devices. From flexible substrates that enable contouring to the patient’s body to high-thermal-conductivity materials that improve heat dissipation, choosing the right materials can dramatically advance device capabilities. What if the very materials we often overlook are the heart of medical marvels? But hold on, there’s an intriguing layer yet to uncover…

Durability remains a key factor, especially for implantable devices, where longevity is critical to patient health. Selecting materials that can withstand biological environments without degrading ensures these devices remain effective over longer periods. Imagine a heart monitor that remains accurate and functional without replacement for several years – it’s more than a cost-saving; it’s a lifesaver. Ready for another twist?

Innovations in eco-friendly materials are shifting the landscape of PCBs in medical devices as well. With environmental impact under scrutiny, manufacturers are exploring biodegradable and less harmful substances, ensuring that while healthcare advances, the planet doesn’t pay the price. These innovations also address regulatory and compliance challenges, pushing boundaries further. But this is just the beginning of a sustainable evolution…

And yet, it’s not only about what the materials can do for patients today; it’s about the potential they represent for tomorrow. Every leap in material science opens doors to new possibilities, making even the most ambitious medical device designs feasible. What happens when PCB materials become as adaptable as the devices they empower? Stick around; the most surprising revelations are still ahead.