PCB Design Solutions For Medical Devices

Design Complexity: A Double-Edged Sword

Complexity in PCB design is not uncommon; in fact, it’s becoming a norm within the medical technology sphere. With the need for more features and functionalities packed into smaller devices, design intricacies have risen dramatically. But it’s not always complexity for complexity’s sake; it’s a balancing act of sophistication and practicality. And here lies a hurdle few anticipate…

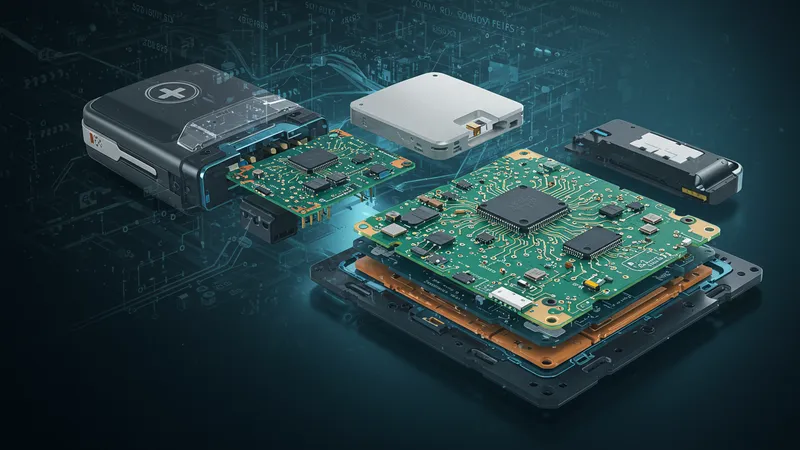

Innovation demands complexity. Advanced multi-layer PCBs and intricate circuit layouts are necessary to support the growing demands for device performance and connectivity. This complexity, however, requires robust tools and skilled professionals, at times making it harder for smaller companies to compete. This could potentially slow down innovation, or does it present a new opportunity to simplify? Dive deeper with us to learn more…

There’s a persuasive argument that complexity also brings resilience. Devices must function flawlessly in unpredictable environments, and feature redundancy within complex designs ensures that even if one section fails, the device continues to operate. This resilience strengthens trust across the medical industry that these devices work under pressure. But it’s also a call for simplification, a fine balance yet to be struck. Are we ready to embrace this harmonious approach?

Moving forward, collaboration becomes key. Listed are cross-industry collaborations with tech giants, bringing diverse expertise to solve unprecedented challenges of PCB complexity. By merging perspectives, the medical tech world becomes less about competition and more about shared advancement, ensuring devices aren’t just complicated, but comfortably complex and consistently impressive. What comes next could be the key to a breakthrough in synergy and innovation…