Enhancing Manufacturing Productivity Through Cutting-Edge Tooling Techniques

The Unseen Boost: How Tech Enhances Tooling Accuracy

Technological advances in tooling are providing unprecedented accuracy in manufacturing processes. Digital calibration systems mean that even the smallest errors can be detected and corrected in real-time.

This precision leads to fewer defects and reduces waste significantly. For instance, companies report up to a 40% reduction in material wastage. But let’s delve deeper…

The implementation of AI in tooling raises the stakes high. By predicting the necessary changes ahead of time, AI doesn’t just save time; it ensures near-perfect precision. Ready for the next revelation?

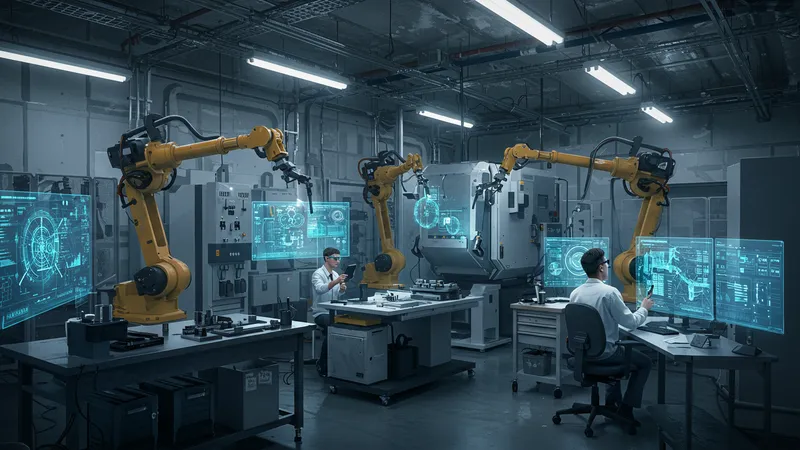

With robotics also entering the fray, humans and machines are collaborating in the manufacturing space like never before. It’s more coordinated, more sophisticated, and poised for exponential growth. Hold on—the surprises continue.