Supply Chains Become Green Agile And Tech Enabled

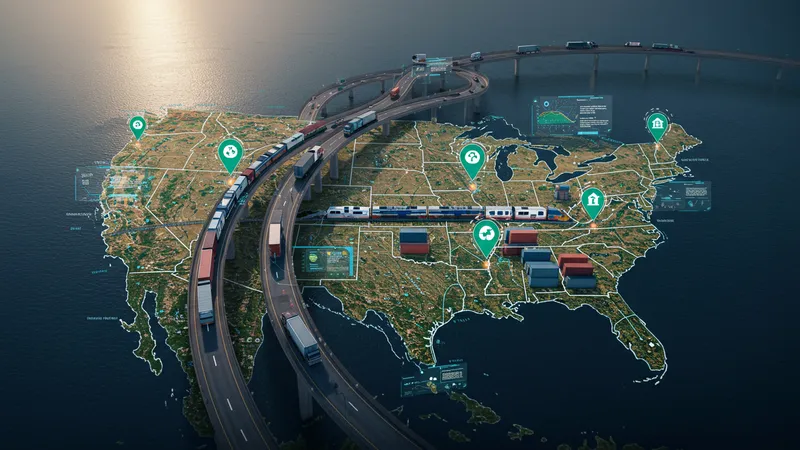

Imagine a complex web, where products move seamlessly from factories to homes across every corner of the United States. Behind this flow lies an evolving philosophy: making supply chains responsive to change, environmentally responsible, and powered by the latest digital technologies. This means transforming traditional logistics into networks that can quickly adjust to disruptions, reduce waste at every step, and rely on real-time visibility. Three pillars drive this evolution: environmental stewardship, nimbleness in shifting conditions, and leveraging digital tools to orchestrate each link in the chain.

In the United States, this modern approach means companies are reimagining their operations to keep up with consumer demand, new regulations, and the unpredictability of global trade. By incorporating sustainable practices, building in rapid adaptability, and integrating advanced platforms, logistics providers and manufacturers are reshaping their business landscape and forging a smarter, cleaner future for delivering goods.

- SAP Integrated Business Planning – Advanced supply chain planning platform; typical enterprise cost: $150,000+/year.

- IBM Supply Chain Insights – AI-driven analytics for enhanced agility; starts around $120,000/year.

- Oracle SCM Cloud – Cloud-based supply chain management and sustainability tracking; varies from $5,000 to $15,000/month depending on scope.

The move toward cleaner, faster, and tech-enabled supply chains is more than a trend: it’s rapidly becoming a requirement. Pressure from U.S. regulators and consumers has forced companies to rethink carbon emissions and resource usage. Digitalization accelerates this shift, providing clear data for smart environmental decisions and responsive operations during disruptions like natural disasters or changing tariffs.

Consider the difference real-time analytics brings when a port closure suddenly halts imports. Green, agile, and technology-driven systems enable immediate rerouting, dynamic inventory sourcing, and minimize unnecessary transportation, saving fuel and emissions. Companies adopting these strategies also find themselves better positioned for compliance with new EPA standards and climate-focused business incentives found throughout the United States.

Another key aspect is building supply chains that don’t just respond but anticipate. Solutions like Oracle SCM Cloud help organizations predict demand spikes and supply disruptions, while SAP’s platform ensures minimal waste through demand-driven planning. These systems enable greater synchronization between suppliers, manufacturers, and retailers, making agile and green logistics possible even at immense scale.

Finally, early adopters are setting the pace. U.S. companies like Unilever and Tesla are leveraging technologies such as machine learning-based route planning, blockchain for transparent sourcing, and IoT sensors to watch emissions in real-time. The cumulative effect is transforming how goods are produced, moved, and delivered in the United States—setting standards for the rest of the world.

This is only the starting point. The deeper details reveal even more valuable insights ahead—such as how these systems impact costs, customer satisfaction, and America’s competitive edge on the global stage…