Understanding Centrifugal Separators: Key To Efficient Separation Processes

Did you know that some of the world’s most advanced separation processes rely on technology developed over a hundred years ago? That’s right, centrifugal separators are revolutionizing industries by refining efficiency and precision in ways you wouldn’t believe.

With environmental concerns reaching critical levels and industries demanding ever-greater efficiencies, understanding how centrifugal separators work is more crucial now than ever before. More businesses are discovering their potential – and the results are astounding.

- GN Solids Control: Known for its rugged reliability used in oilfields worldwide, starting at $50,000 per unit.

- Trucent: Leveraging automation to triple throughput, with pricing from $30,000 per system.

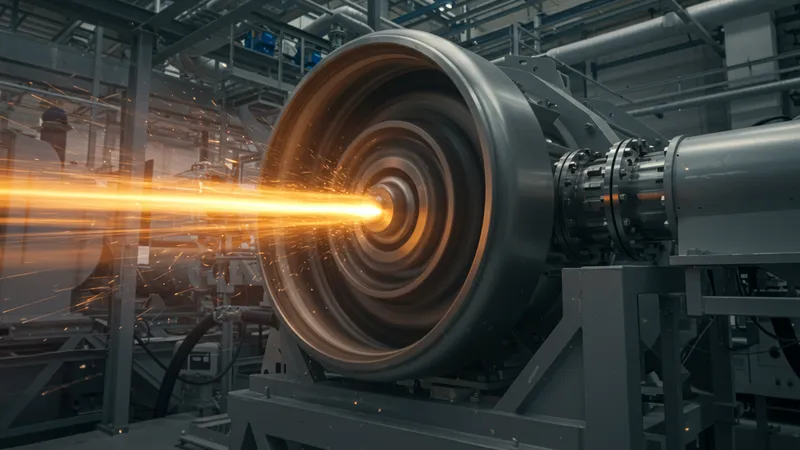

Here’s something surprising: centrifugal separators weren’t always the sleek, high-functioning machines they are today. Their history traces back to the 19th century when basic spinning bowls were used for cream separation, leading to unexpected advancements in a wide range of fields. Today’s iterations harness mind-boggling speeds that apply near-critical force to split mixtures into their component parts, revolutionizing both food production and chemical processes. But that’s not even the wildest part…

The real magic of centrifugal separators lies in their adaptability. From transforming raw milk into high-quality dairy products to purifying precious metals and even in life-saving medical applications, their versatility is unmatched. They’ve become an unsung hero in the drive towards sustainability, as they effectively reduce waste and increase operational efficiency. What happens next shocked even the experts…