Understanding Centrifugal Separators: Key To Efficient Separation Processes

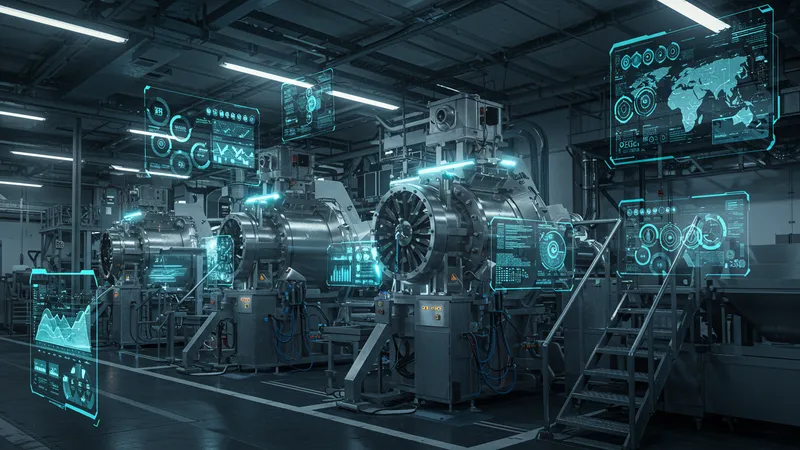

Smart Manufacturing Meets Centrifugal Technology

The intersection of smart manufacturing and centrifugal technology represents a digital revolution. By integrating data analysis, these systems can significantly reduce energy use while enhancing performance. It’s a synergy that marries technology with tangible industry progress. But zoom in…

A modern factory equipped with smart centrifugal separators experiences enhanced workflow integration, where data-driven insights optimize efficiency without human intervention. As this approach spreads, operations are streamlined, cost-effective, and more sustainable. But there’s another layer of intrigue…

The potential for remote monitoring and adjustment allows industries unparalleled control over their processes, minimizing losses while maximizing output. These advancements make way for significant cost savings and enhanced product quality. Yet there’s another crucial twist…

Encouragingly, these systems support sustainability by promoting reduced waste and energy-efficient operations. Industries utilizing these innovations are setting a high bar for what environmentally-friendly practices should look like in the modern age. Uncover what else is driving this change…