Understanding Centrifugal Separators: Key To Efficient Separation Processes

The Astonishing Evolution of Centrifugal Separators

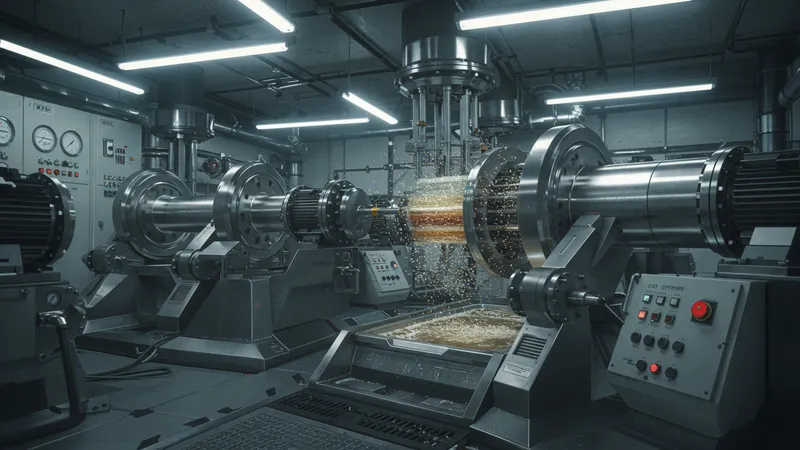

Initially utilized for cream separation in the dairy industry, centrifugal separators quickly found their niche by exploiting the physics of centrifugal force. The evolution from simple bowl designs to the complex rotor-driven systems we see today signifies a leap in technological innovation with profound impacts. Modern separators achieve speeds that create g-forces several thousand times that of gravity, allowing precise separation of particles in suspensions. But there’s one more twist…

In the oil and gas sectors, these technologies have been pivotal. Early centrifugal devices laid the groundwork for today’s highly sophisticated versions, which can separate mud from valuable hydrocarbons almost effortlessly. This capability has significantly reduced waste, turning what was once considered a byproduct into a valuable resource. And just when you think it couldn’t get better…

Within the pharmaceutical industry, centrifugal separators play a crucial role in the manufacturing of vaccines and medicines. By facilitating the separation of active ingredients from complex mixtures, they help ensure purity and safety, which are paramount in health products. And the story doesn’t end there…

The application of centrifugal separation in environmental technology is groundbreaking. Wastewater treatment plants use these machines to effectively remove particulates from liquids, contributing to cleaner water systems. This innovation not only aids in reducing pollution but also in reclaiming water for industrial reuse. What you read next might change how you see this forever.