Understanding Grinding Machines: A Comprehensive Overview

The Adaptive Evolution of Grinding Technology

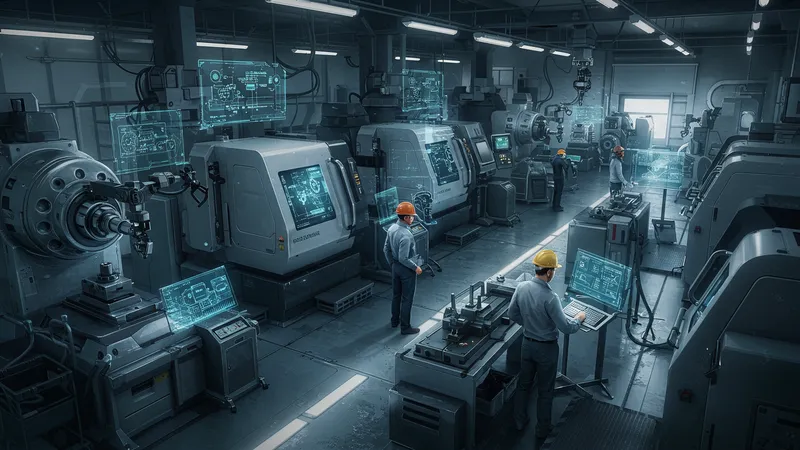

In a world rapidly embracing the fourth industrial revolution, grinding machines have shown remarkable adaptability. With shifts towards Industry 4.0, these machines are on the cutting edge of technological advancements. What’s captivating is how they continue to evolve…

From manual calibration to digital integration, the transition has been nothing short of transformative. Today’s grinding machines can self-monitor, self-correct, and even predict necessary adjustments, ensuring optimal performance at all times. But there’s a more intriguing attribute to these adaptations…

Artificial intelligence is unlocking new capabilities within grinding machines, enabling them to learn from past operations and improve future outcomes. This results in continuous enhancement and a reduction in machine downtime, creating a smarter, more efficient production environment. Yet, the scope of these advancements stretches even further…

Such innovations are setting up a paradigm shift where grinding machines not only perform tasks but are also involved in decision-making processes. These smart systems are reshaping the backbone of manufacturing, promising a future of boundless possibilities. There’s an exciting revelation that might transform the manufacturing sector at its core…